During the interview, the reporter found that some grain processing enterprises have also introduced new technologies through research and development and extended the chain of intensive processing industries, so as to reduce the loss of grain in the processing link.

The grain industry in Jiangxi is mainly indica rice. the reporter learned that after 100 jin of indica rice is shelled, there is about 80 jin of brown rice, and due to the increasing demand for precision and whiteness in the market, traditional technology is used to process brown rice into white rice.

Yang Ping: the samples we are seeing now are rice processing enterprises according to the situation of rice processing by-products and finished rice formed by the production and processing of half a jin of rice. After more than 20 processes, half a jin of rice finally forms the finished rice, and its weight is only about half of that of rice.

The reporter learned in the interview that in recent years, the state has promoted the consumption of whole grain food, while at the same time, through technological innovation, the promotion of flexible grinding and other technologies to reduce the loss of processing links.

The reporter saw in Wan'an, a grain processing enterprise, that rice shelling, rice milling, polishing and other processes have all been intelligentized, and flexible grinding technology has been used, which has greatly reduced processing losses.

Yin Shuibin, director of the rice processing plant of Jiangxi Yijiang Autumn Grain and Oil Co., Ltd.: the technology of light grinding and cold polishing has been adopted, and the rice yield per 100 jin of rice has been increased by 4%.

Wang Fengzhong, director of the Agricultural products processing Institute of the Chinese Academy of Agricultural Sciences: it used to be milled many times, but now the number of milling layers is lower, that is, it retains more nutrients in our rice, so that its rice yield can be improved.

The reporter saw in the interview that not only the processing technology is making innovative breakthroughs, but the industrial chain is also extended to rice noodles, rice vinegar and other intensive processing, and by-products such as broken rice are also fully utilized.

Anyi, an enterprise, has reduced the loss rate of grain processing from 8% to 2.5% by taking measures such as not polishing rice, less polishing, and producing rice noodles with broken rice.

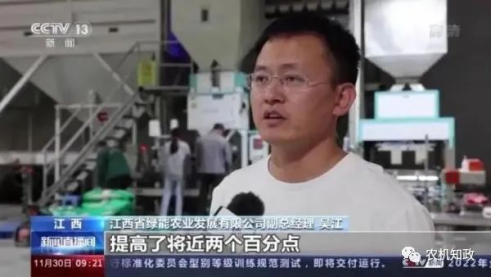

Wu Jiang, deputy general manager of Jiangxi Green Energy Agricultural Development Co., Ltd.: through two technological reforms, we have added related facilities to increase the rice yield of traditional rice processing by nearly two percentage points, and can produce an additional 300 tons of rice every year.