The latest agricultural situation dispatch of the Ministry of Agriculture and villages shows that at present, China's autumn grain harvest is coming to an end, with the exception of some middle and late rice and late autumn crops in the south, other harvests have come to an end.

This year, the areas of summer grain, early rice and autumn grain have all increased in the three crops throughout the year.

The per unit yield of summer grain and early rice increased, and the per unit yield of corn and soybean increased significantly in many main autumn grain producing areas.

Judging from the actual harvest in various localities and reflected in many aspects, the grain harvest for the whole year will be good again.

Grain saving and loss reduction to ensure food security.

Although there has been another bumper grain harvest this year, with the increasing environmental constraints on resources such as fresh water and cultivated land, it is becoming more and more difficult to increase the area and output of grain.

Therefore, China regards grain loss as an important starting point to ensure food security, and continues to take effective measures to reduce food loss and waste in all aspects of the whole chain.

What is the current situation of global food losses?

What positive progress has been made in grain conservation and impairment in China?

According to the United Nations Food and Agriculture Organization, the annual loss of global food from production to retail accounts for about 13.9% of the world's food output.

A 1 percentage point reduction in this loss is equivalent to an increase of more than 27 million tons of grain, enough to feed 70 million people for a year.

In our country, the loss rate of the whole grain chain is up to 8%.

Among them, production and harvest accounted for about 27% of the total grain loss and waste, storage and transportation accounted for about 33%, processing and packaging accounted for about 9%, and consumption accounted for about 31%.

To save grain and reduce losses is to increase production and ensure supply.

In recent years, our country has focused on the reduction of machine income, the improvement of facilities and equipment, and the promotion of grain conservation.

This year, the reduction of grain consumption has become a bright spot in the whole grain chain.

Positive progress has been made in the reduction of grain machine harvest in China.

Machine income impairment is an important measure to reduce grain consumption. What is the effect this year?

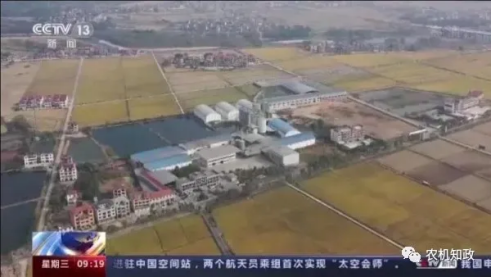

Jiangxi is a major double-cropping rice production province in China, and when the reporter came here, the harvest of late rice was coming to an end.

In Fenggang Township, Yugan County, which is located in the Poyang Lake Plain, the reporter saw that after the agricultural mechanic arrived at the rice field with a harvester, he did not immediately go down to harvest, but took a tape measure to measure the rice.

Yu Fenghua, a farm mechanic in Yugan County, Shangrao City, Jiangxi Province: the length of rice ears varies from field to field. We will measure the height of rice so as to control the position of the harvester. Basically every grain can enter the machine granary smoothly.

After determining the rice harvest height of the field, four agricultural machinists opened their posture and made every effort to harvest.

The reporter learned in the interview that in order to increase grain output, more than 6800 agricultural machinery drivers were trained in rice harvesting skills at the city and county levels in Jiangxi Province before the autumn harvest.

Yu Wenbing, deputy director of the Agricultural and Rural Bureau of Yugan County, Shangrao City, Jiangxi Province: we have achieved loss reduction and efficiency through machine collection training and standardized operations, with a loss rate of about 2.66%.

The reporter learned that since last year, the Ministry of Agriculture and Village has continuously focused on tapping the potential of machine harvest reduction in ensuring food security, and guided various localities to effectively achieve machine harvest reduction through tackling key scientific and technological problems and machine harvest training.

Wang Fengzhong, director of the Agricultural products processing Institute of the Chinese Academy of Agricultural Sciences: on the one hand, we have done a lot of scientific and technological research on our applicable agricultural machinery, and it has also made many vehicles or harvesting machinery more suitable for harvesting.

On the one hand, it is a timely harvest.

Data from the Ministry of Agriculture and villages show that last year, the income and loss rate of the three staple grain machines decreased by an average of 1 percentage point, recovering the loss of 10 billion jin.

This year, the yield and loss rate of summer grain, early rice and autumn grain is also controlled within a reasonable range.

Drying technology and equipment to help save grain and reduce damage.

In China's grain reserves, small farmers and new agricultural operators account for about 40% to 50% of the total grain output, and the post-natal loss is as high as 8% due to improper reserves.

This year, the Ministry of Agriculture and villages has promoted grain drying and other technologies as the key technology for postpartum loss reduction in the main producing areas.

Among the three staple grains in China, about 5% of wheat, 50% of rice and 70% of corn are stored by small farmers and new agricultural operators, which is also the variety with the most postpartum loss.

Shandong Plain is a major corn production county. At present, the local corn harvest is over and is being put into storage one after another.

What is different from the past is that many farmers here omit the drying link this year and send the corn directly into the grain drying tower after threshing.

Zhang Yansheng of Luwang Agricultural Service Center on the plain land of Dezhou City, Shandong Province: after drying, the moisture of corn can be controlled to less than 14% and can be directly stored in storage.

The reporter learned in the interview that the water content of corn was generally more than 35% when it was just harvested. In order to meet the storage standard, the traditional natural drying and air drying needs at least five sunny days.

Cui Yuanyong, a farmer in Pingyuan County, Dezhou City, Shandong Province: for example, I have planted more than 1000 mu of land. When it comes to harvest, the biggest headache is to find a drying ground.

Take corn, for example, it needs seven or eight football field-sized drying grounds, and when drying, the birds also come to eat. The biggest headache is the rainy and cloudy days, which will inevitably cause some losses.

According to the Chinese Academy of Agricultural Sciences, farmers lose 2% to 3% of their corn when drying, and nearly 12% due to improper storage such as mildew and rodent damage.

In order to promote grain conservation and loss reduction, this year, Shandong Plain has built a number of agricultural service centers in villages and towns with services such as drying and warehousing, including 23 grain drying bases, with a drying mechanization capacity of 62.1%.

At the same time, in cooperation with the Agricultural products processing Institute of the Chinese Academy of Agricultural Sciences, the research and development of grain storage mildew online intelligent monitoring and early warning system and accurate prevention and control technology to reduce the post-natal loss of corn to less than 1%.

Wang Fengzhong, director of the Agricultural products processing Institute of the Chinese Academy of Agricultural Sciences: through this green and low-carbon processing method, both corn and wheat can be dried in time, so that the loss of our entire grain should be reduced.

In recent years, the central government has increased subsidies for the purchase of grain drying machines and tools, and the Ministry of Agriculture and villages has also vigorously promoted practical technologies such as drying and mildew prevention and control.

This year, the loss of grain in drying and storage has been further reduced.

Help to save grain and reduce losses: moderate processing to extend the industrial chain.

During the interview, the reporter found that some grain processing enterprises have also introduced new technologies through research and development and extended the chain of intensive processing industries, so as to reduce the loss of grain in the processing link.

The grain industry in Jiangxi is mainly indica rice. the reporter learned that after 100 jin of indica rice is shelled, there is about 80 jin of brown rice, and due to the increasing demand for precision and whiteness in the market, traditional technology is used to process brown rice into white rice.

Yang Ping: the samples we are seeing now are rice processing enterprises according to the situation of rice processing by-products and finished rice formed by the production and processing of half a jin of rice. After more than 20 processes, half a jin of rice finally forms the finished rice, and its weight is only about half of that of rice.

The reporter learned in the interview that in recent years, the state has promoted the consumption of whole grain food, while at the same time, through technological innovation, the promotion of flexible grinding and other technologies to reduce the loss of processing links.

The reporter saw in Wan'an, a grain processing enterprise, that rice shelling, rice milling, polishing and other processes have all been intelligentized, and flexible grinding technology has been used, which has greatly reduced processing losses.

Yin Shuibin, director of the rice processing plant of Jiangxi Yijiang Autumn Grain and Oil Co., Ltd.: the technology of light grinding and cold polishing has been adopted, and the rice yield per 100 jin of rice has been increased by 4%.

Wang Fengzhong, director of the Agricultural products processing Institute of the Chinese Academy of Agricultural Sciences: it used to be milled many times, but now the number of milling layers is lower, that is, it retains more nutrients in our rice, so that its rice yield can be improved.

The reporter saw in the interview that not only the processing technology is making innovative breakthroughs, but the industrial chain is also extended to rice noodles, rice vinegar and other intensive processing, and by-products such as broken rice are also fully utilized.

Anyi, an enterprise, has reduced the loss rate of grain processing from 8% to 2.5% by taking measures such as not polishing rice, less polishing, and producing rice noodles with broken rice.

Wu Jiang, deputy general manager of Jiangxi Green Energy Agricultural Development Co., Ltd.: through two technological reforms, we have added related facilities to increase the rice yield of traditional rice processing by nearly two percentage points, and can produce an additional 300 tons of rice every year.

Four major measures to promote grain conservation and impairment.

The Ministry of Agriculture and villages said that during the 14th five-year Plan period, China will focus on four aspects, effectively reduce the loss of grain production, storage, transportation and processing, and carry out grain conservation actions.

These four major measures should attach equal importance to increasing revenue and reducing expenditure, increase production and reduce losses, vigorously promote the reduction of the whole chain, and systematically reduce the loss and waste of grain.

First, strengthen the control and control of the source of production, promote precision sowing and appropriate sowing, reduce the number of seeds used in agricultural production, promote the mechanization of grain production, raise the level of standardization of machine harvesting operations, reduce the loss of harvesting process, and ensure that particles return to the warehouse.

The second is to strengthen the loss of storage and transportation links, develop grain post-natal drying, improve grain storage and quality assurance, pest and mold control and other conditions, improve the rural logistics node network system, promote special tools for bulk grain transportation, and reduce leakage.

The third is to improve the level of processing and utilization, establish a standard system for moderate grain processing, optimize processing technology and equipment, and improve the yield of grain products and the comprehensive utilization rate of by-products.

Fourth, guide saving and rational consumption, improve service norms and industry standards in the catering industry, routinely promote CD-ROM action, carry out a series of publicity activities to love grain and save grain, and promote strict economy and oppose waste.

Source: agricultural machinery know the government